- Alle Produkte

- FASEP B212 Nano-Auswuchtmaschine

E622.026

FASEP B212 Nano-Auswuchtmaschine

https://www.garagepro.ch/shop/e622-026-fasep-b212-nano-auswuchtmaschine-51916 https://www.garagepro.ch/web/image/product.template/51916/image_1920?unique=c259d4cFASEP B212 nano

Die neue Generation der Ultrakompakten.

Mit seinem ultrakompakten Design bietet der B212 die grundlegenden Funktionen für ein sicheres und präzises Auswuchten von Rädern.

Der Platzbedarf wird durch die Möglichkeit, alle Funktionen und Sonderoptionen einzubauen, um jeden Radtyp perfekt auszuwuchten, minimiert.

Das Herzstück der Auswuchtmaschine ist das TriSensor-System, ein exklusives FASEP-Design, und das IFS-System (integrierte Flanschwelle) für maximale Zentriergenauigkeit.

https://www.garagepro.ch/web/image?model=product.image&id=3247&field=image_1920&unique=1741779692000

B212_NANO

12

1420

1420

0

marker

3D Console to access all functions.

296

588

0

marker

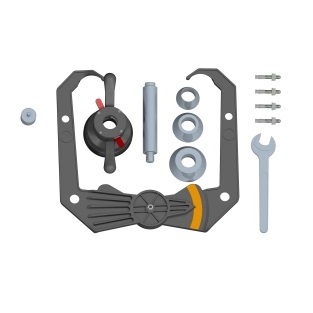

Compartments for weights (6), cones (3) and tools (1).

419

493

0

marker

Flange holder (4).

681

348

0

box_left

ALU-SE

Automatic input/gauge to measure and apply stick-on weights

456

848

71384

TRI_SENSOR

box_right

Tri-Sensor

3 sensors system.

588

1140

71385

IFS

box_right

IFS

Integrated-flange shaft system.

679

1138

71713

box_bottom

75 kg

1015

1071

71307

box_bottom

256

angular positions

1028

1186

71319

box_bottom

RPM

98 low speed

1030

1313

71313

box_bottom

16 bit

high resolution

1112

1071

71716

box_bottom

FLASH MEMORY

technology

1123

1214

71321

box_bottom

SPLIT

weight function

1132

1335

3 Sensors system

for unbalancing measurement

- NO no need of mechanical ties

- YES it is stable by itself

- YES the centrifugal force goes completely through the sensors

- YES the unbalance is completely measured

- YES with each type of wheel, also of large size or width, results are always perfect

FASEP wheel balancers are built around the TriSensor System,

a FASEP exclusive design. Developed in collaboration with

the University of Florence, TriSensor is a system for measuring

vibrations designed so that mechanical ties do not influence

the measuring system. By mean of the 3-sensors, the system

is “intrinsically stable” and no strong mechanical ties are

needed.

On the contrary, in the 2-sensors systems, the presence of one

or more mechanical ties alters the measurements of vibrations,

as the vibrations may not completely go through the sensors

but, at least partially, they go through the mechanical ties.

In TriSensor System, the centrifugal force caused by the

unbalance goes completely through the sensors as there is

no other mechanical tie. In such way, the vibration force is

therefore completely known and measured. This makes sure

that in every condition and with any type of wheel, wide small

or, measurements will be always perfect.

INTEGRATED FLANGE Shaft

for a perfect centering

-

The bell flange is integrated in the shaft.

It doesn’t need to be mounted.

No tolerance of coupling. -

The rear spring for the use of the inner cone

is integrated in the shaft. It is not necessary

to mount it and it is protected against dirt,

facilitating the operator in mounting the wheel. - Inner cone. Centering is absolutly easy and accurate.

- YES the bell flange is integrated in the shaft

- NO it doesn’t need to be mounted

- NO dirt or usury

- YES tolerances of coupling are eliminated

- YES it improves dramatically the centering accuracy

A cutting edge technology | SOFTWARE VIDEOTRONIC.CE

Innovative balancing program.

AUTOSELECT

Automatic Selection of Balancing Mode

The AUTOSELECT system allows automatic selection of Balancing mode (Dynamic, Alu-S1, Alu-S2) when wheel is measured. According to how measures are taken, AUTOSELECT automatically select Dynamic mode (2 clip weights), Alu-S1 (1 clip weight + 1 stick on weight) or Alu-S2 (2 stick on weights).

WOW

Wizard of Weight

WOW is a function that is designed to reduce costs by limiting the quantity of wheel weight required to balance a wheel to within an acceptable and satisfactory tolerance. The other major benefit has to be aesthetics because makes carrying out a behind spoke balance.

G3.EXTREME

Minimize working time.

1. APS 2

AUTOSELECT 2

G3.EXTREME news:

- Electronic motor control (inverter).

- Use of quiet and powerful three-phase motor.

- Very quick cycle time (start-up, braking and automatic wheel positioning in 5,5 sec.).

- Automatic positioning system APS2 faster and more accurate, controlled by the keyboard or the brake pedal.

- Electromagnetic brake included as standard.

- 50-60 Hz seamless operation (electronic motor control operates shaft always at same speed).

LASER TECHNOLOGY

For application of adhesive weights.

LASER LINE : LASER BASIC TECHNOLOGY

Simple, accurate, economic.

LASER BASIC ADVANTAGES:

- After the measurement run, easily determine the point of application in the visible area at the bottom of the inside of the wheel rim.

- Clean the area of application of the weight, without problems, as it is clearly visible where the weight will be applied, in the area illuminated by the LASER LINE.

- Apply the adhesive weight easily and accurately, without problems of incorrect weight angle as it can happen manually with the traditional Alu-S/Alu-SE systems operating in the upper part of the rim and then in one area not visible to the operator.

LASER POINT : LASER BASIC TECHNOLOGY + LASER POINT

Straight to the point.

LASER BASIC ADVANTAGES

+ LASER POINT ADVANTAGES:

- Apply the adhesive weight, very accurately, with no chance of mistake even by a few millimeters as the LASER is just a dot.

- Identify, from the start, that is during input of rim dimensions, the point of application of weights to avoid areas of the rim that are not flat.

3D TOUCHLESS INPUT : LASER BASIC TECHNOLOGY + LASER POINT + 3D TOUCHLESS

Wheel measurement and balancing completely automatic

LASER BASIC ADVANTAGES

+ LASER POINT ADVANTAGES

+ 3D TOUCHLESS ADVANTAGES:

- The 3D Touchless Input system automatically measures the wheel data (distance + diameter + width) both for alloy and for steel rims, allowing balancing with both stick-on and clipon weights, respectively.

3D TOUCHLESS INPUT

System for automatic measurement of the wheel.

Laser for automatic measure of the wheel.

Automatic apply of stick-on weights.

External measuring system.

The 3D Touchless Input systems automatically measures the wheel data (distance + diameter + width) both for alloy and for steel rims, allowing balancing with both stick-on and clipon weights, respectively.

PNEU-LOCK

Accuracy in clamping.

PNEULOCK system in balancers without automatic tilt system.

PNEULOCK system in balancers with automatic tilt system.

Most FASEP wheel balancers can be equipped with PNEULOCK system for accurate clamping of the wheel.

With the FASEP PNEU LOCK, you have a lot of advantages:

- effortless accurate clamping of the wheel, without fatigue

- safe operation

- system operates even in the event of malfunction of pneumatic system or lack of compressed air

3D.Scan / 3D.Wall

Automatic scanner system.

3D.Scan

- Run-out

- Conicity

- Side slip

3D.Wall

- Run-out

- Conicity

- Side slip

- Tire Profiler

Side-slip measure

Side slip test

MAIN FUNCTIONS

- Point-by-point measure

- Maximum deviation

- First harmonic

- Point of maximum deviation

- Side-slip for 4 wheels

3D.Wall

Mounting position of the 4 tires, analyzed individually, to achieve the lowest overall drift of the machine.

The new automatic SCANNER system for Videotronic.CE machines is based on motorized SONAR sensor. The SCANNER control system allows to measure the run-out of tire and rim with 1mm accuracy, as well as Side Slip of tire. It completely integrates with Videotronic.Ce software.

TOP-LIGHT

Light and laser

WITHOUT TOP-LIGHT

Possible positioning error

WITH TOP-LIGHT

Laser shows right position

Top-Light is the new FASEP equipment for working in optimal lighting conditions. Two light points to improve brightness in the working area, and two lasers to show with great accuracy the position of the weight to be applied on the tire.

LED LIGHT

LED lighting for the inside the rim.

Wheel NOT lighted

Wheel lighted with LED-LIGHT

Données technique

- Automatische digitale Radauswuchtmaschine

- - Geeignet für Pkw-, SUV- und Transporter-Räder

- - 32-Bit-G6-Elektronik. Elektronische Motorsteuerung SMART

- - Drehstrommotor mit elektronischer Steuerung (inverter)

- - Niedrige Geschwindigkeit (98 RPM)

- - Bedienfeld mit Multifunktions-Tastatur (Doppel-LED-Anzeige)

- - BASIC-Programm zur Nivellierung

- - Integriertes Flanschsystem IFS Light (max 75 Kg)

- - TRI-Messsystem. 3-Piézo S3NSOR

- - - 40-mm-Welle

- - Höhe des Stiels vom Boden aus 665 mm

- - Länge. Schaft 210 mm

- - 256-Punkt-Positionssensor

- - Kompakte Basis

- - Radbremse mit Schnellkupplung

- - DCB-Elektrobremse (Bremse in Position)

- - Automatische Start-Stopp-Funktion

- - Stop-On-Top (Bremsen in der 12-Uhr-Position)

- - Automatische 2D-Datenerfassung (Abstand + Durchmesser)

- - ABS-Gewichtsstütze (6 Fächer, 3 Kegelhalter, 1 Werkzeughalter)

- - Automatische Kalibrierung mit Probengewicht

- - Selbst-Diagnose

- - ALU-Leichtmetallradprogramm

- - ALU-SE / Alu-PAX-Programm für die geführte Anwendung von Klebegewichten

- - MOTO-Programm

- - Programm zur Benutzerkonfiguration

- - Programm SPLIT (versteckte Gewichte)

- - MARS Programm zur Minimierung der statischen Elektrizität

- - Programm STATISTIK

- - FCC-Kalibrierungsprüfprogramm

- - Kegel 42–98 mm

- - Maximales Radgewicht 75 kg

- - Raddurchmesser 10-26"

- - Maximaler Raddurchmesser 864 mm (34")